1.Application of Gecko Adhesive

2.Double-sided suction cup, double-sided low viscosity and removability

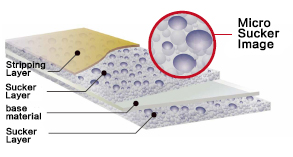

Based on the principle of nano-scale micro-sucker adhesion, the technology of Gecko Adhesive overturns the principle of traditional glue chemical adhesion. The inkjet film can be pasted repeatedly on the clean and smooth surface under the ideal environment, and does not damage the surface of attachments.

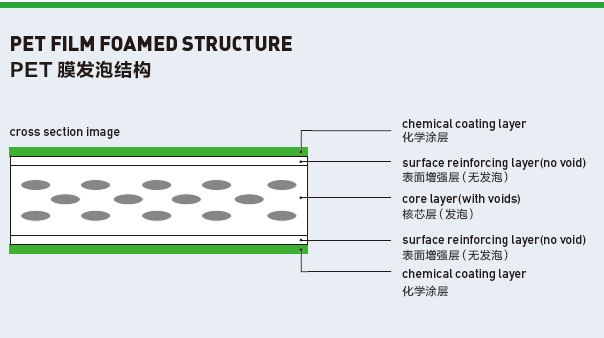

3.Top-class foamed PET core materials

The foamed PET inkjet film is thin and light. The core layer has a foamed structure, which is impact resistance, wear resistance, chemical resistance and heat resistance. Moreover, the surface coating layer has an excellent ability to regenerate PET.

4.Low viscosity

Glue surface needs to be contacted during the pasting operation. You may not feel the glue due to low viscosity, which is liable to release film materials and beneficial to easy operation.

1.Flexible application of double-sided suction cup

The glue surface adhered to a base can be removable, and the contact surface adhered to an adherend can be also removable, which creates the flexible application of everyday items.

2.High tenacity, high stiffness and tear resistance

The special PET film materials possess the outstanding properties of heat resistance, chemical resistance and wear resistance. The double-faced adhesive tape has high stiffness and good extensibility in use, which is not easy to become a soft ball and thus is more user-friendly.

3.Environment-friendly film materials

The film materials are produced by using regenerative PET materials, which saves material consumption and has no pollution to the environment. In addition, the void structure makes film materials light and easy to use.

4.No adhesive residue

Traditional chemical water glue and oil glue certainly will leave adhesive residue on the surface of attachments during peeling, but the technology of Gecko Adhesive uses micro-suckers to drain away the air, form the micro-vacuum and generate physical absorption, with sufficient viscous force and without adhesive residue after peeling.

5.Easy to operation

No additional adhesive tape is needed during the pasting process. It is suitable for repeated relocation and removal. No professionals are required and green hands can also complete the pasting easily.

Ordinary double-faced adhesive tape mostly belongs to oil glue with strong adhesive force on both sides, which are strongly fixed on a base and an adherend at the same time to realize the connection function. However, the adherend is difficult to move over and over again, and also it is hard to peel the double-faced adhesive tape from the base. Moreover, the double-faced adhesive tape is not environmental-friendly and cannot be used repeatedly.

Gecko double-faced adhesive tape gives full play to the characteristics of suction cup adhesive, like a “gecko suction cup”, which can absorb and desorb freely. It is easy to separate after the completion of connection function. In addition, Gecko double-faced adhesive tape can be pasted and used repeatedly, and there is no adhesive residue on the base.

1.It can be widely applied in the civilian and industrial fields, such as offices, houses, printing, machinery, processing, advertisements, etc.

2.It can be used in a variety of usage scenarios of double-faced adhesive tape, such as photo pasting, announcement pasting, document pasting, protection pasting, fixed positioning, anti-skid pasting, identification pasting, etc.

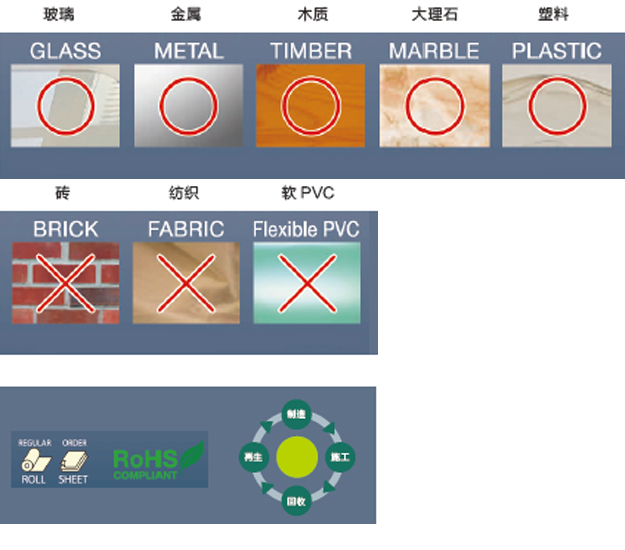

3.It is applicable to be pasted on the following materials:

1.Product appearance: roll materials and sheet materials

2.Product specification: roll materials-roll width 1.0m * roll length 12.5/25/30/50m (The roll length can be customizable); and sheet materials-sheet width 0.6 * sheet length 0.9m

3.Base materials: 50um foamed PET film

4.Glue: 50um Gecko Adhesive+80um Gecko Adhesive, with environment-friendly water-based features and sucker physical absorption features

5.Backing paper: roll materials-120g release paper; and sheet materials-120g+140g release paper

(*Note: Since adjustments can be made by Signscal for parameters and performance of all products according to market demand, the actual product shall prevail)