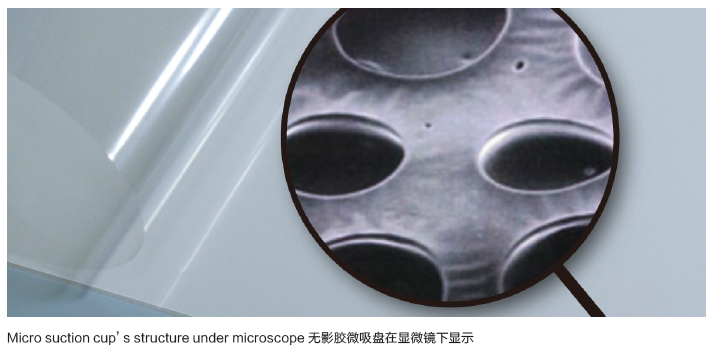

1.Application of Gecko Adhesive

The single-hole self-adhesive film of Gecko Adhesive coating layer is applied.

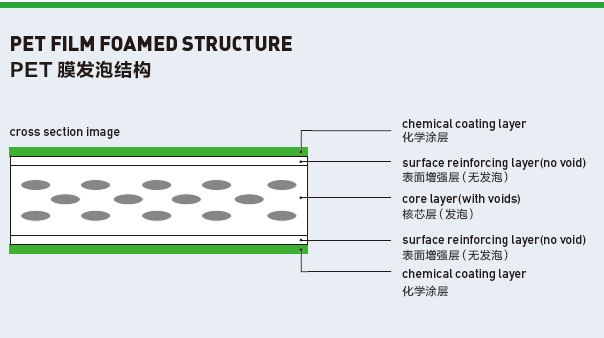

2.Top-class foamed PET surface materials

The core layer has a foamed structure, which is impact resistance, wear resistance, chemical resistance and heat resistance. Moreover, the surface coating layer has an excellent ability to absorb ink and regenerate PET.

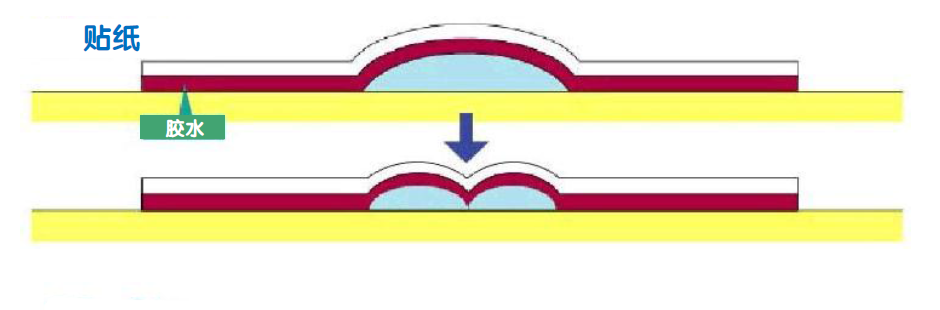

3.Low viscosity

Glue surface needs to be contacted during the pasting operation. You may not feel the glue due to low viscosity, which is liable to release film materials and beneficial to easy operation.

4.Removable adhesive

Ordinary inkjet paster is difficult to achieve real removability and thus goes against construction and repeated pasting, but the removability of Gecko Adhesive can be revealed incisively and vividly.

1.Exquisite images can be shown perfectly

The film coating layer makes UV ink show the best performance ability, and colorful images with rich gradation and granular sensation can be obtained.

2.Image quality can be lasted for a long time

The special PET film materials have consistent high quality, possess the outstanding properties of heat resistance, chemical resistance and wear resistance, and are more suitable for keeping images in high temperature condition because they can guarantee the clearness, fastness and non-deformation of these images.

3.Environment-friendly film materials

The film materials are produced by using regenerative PET materials, which saves material consumption and has no pollution to the environment. In addition, the void structure makes film materials light and easy to use.

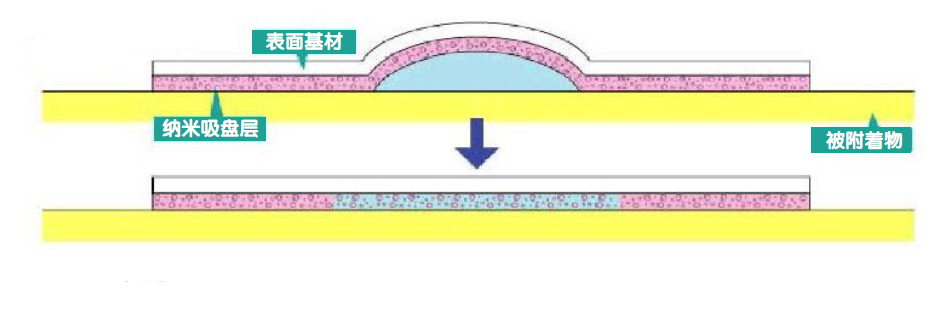

4.Repeated pasting

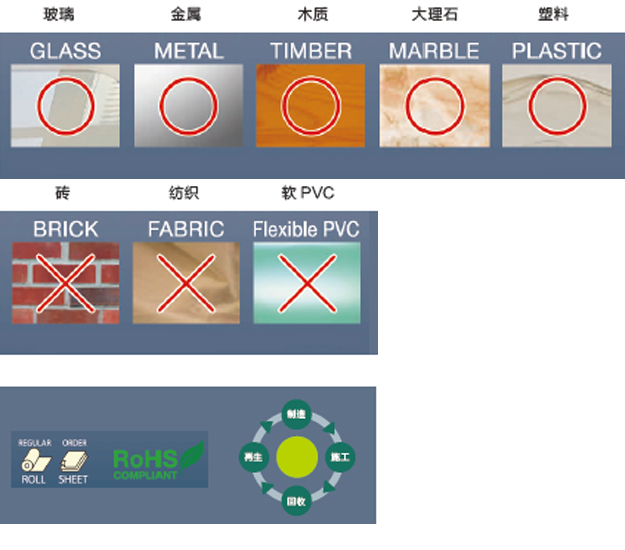

Based on the principle of nano-scale micro-sucker adhesion, the technology of Gecko Adhesive overturns the principle of traditional glue chemical adhesion. The inkjet film can be pasted repeatedly on the clean and smooth surface under the ideal environment, and does not damage the surface of attachments.

5.No adhesive residue

Traditional inkjet paster is hard to realize that there is no adhesive residue, so it is required to clean the surface of attachments during peeling, which wastes time and energy and even may lead to complaints. However, Gecko Adhesive adopts physical absorption and there is no adhesive residue.

6.Easy to operation

No additional adhesive tape is needed during the pasting process. It is suitable for repeated relocation and removal. Green hands can also complete the pasting easily.

Usually, the application of gum needs to spray water constantly to drive away the air and thus realize smoothness of the gum. However, since there are voids linked together between foamed glue in the application of Gecko Adhesive, the air is hard to form large bubbles or is easy to be absorbed, which greatly reduces the difficulty of construction and the labor time of workers.

Glue film is prone to wrinkles and bubbles because there is no passage left for air to leave.

Because the holes are connected with each other, air can be discharged, and it is not easy to produce folds and bubbles.

1.It can be applied in the fields of label, advertising inkjet and poster campaign.

2.It is recommended to be used in various indoor environments such as banks, offices, markets, airports, convenience stores, commercial buildings, etc., as well as electronic products, consumer product labels, etc.

3.It is suitable for UV printing.

1. Outlook: Rolls

2. Size: width 1.37m * length 12.5/25/30m (custom sizes available special order)

3. Face Material: 50um appox, TOYOBO white foamed PET film

4. Adhesive: 80um appox, Gecko, environmentally water-based, suction type adhesive

5. Liner: 120g appox white release paper or 50um PE film

6.Printing inks: UV

7. Minimun Application Temperature: 4℃

8. Service Temperature Range: -17℃~150℃

9. Dimensional Stability: Excellent

10. Humidity Resistance: Excellent

11. Solvent Resisitance: Excellent

12. Water Resisitance: Excellent

13. Expected Lifetime Exterior: Up to 5 year. Repeatable pasting for hundred of times on clean and smooth surface

14. Storage Stability: 2 years shelf life when stored at 21℃ and 50% relative humidity

(*Note: Since adjustments can be made by Signscal for parameters and performance of all products according to market demand, the actual product shall prevail)