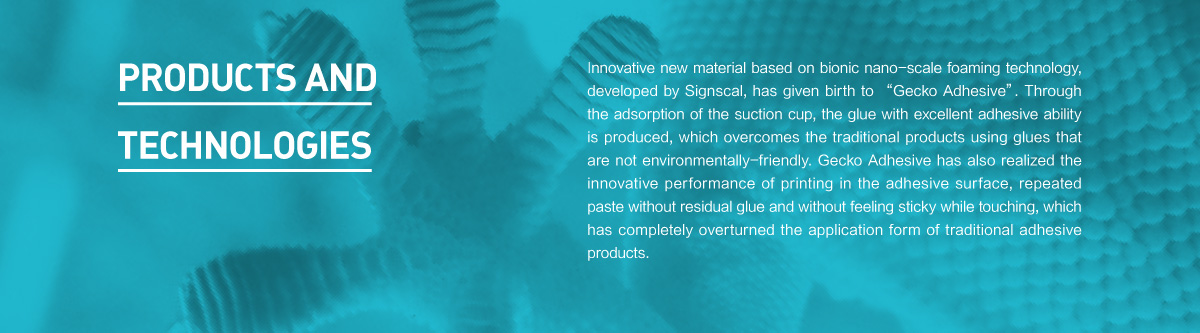

1.Application of Gecko Adhesive

The self-adhesive film of Gecko Adhesive coating layer is applied.

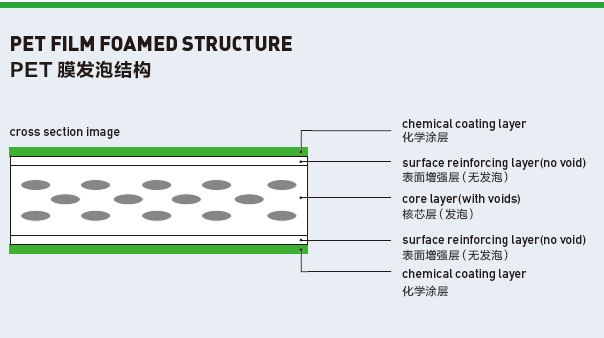

2.Top-class foamed PET surface materials guarantee the clearness, exquisiteness and durability of photos

The foamed PET inkjet film is 125μm in thickness, and the core layer has a foamed structure, which is impact resistance, wear resistance, chemical resistance and heat resistance. Moreover, the surface coating layer has an excellent ability to absorb ink and regenerate PET.

3.A kind of photopaper that can be really pasted repeatedly

Based on the principle of nano-scale micro-sucker adhesion, the technology of Gecko Adhesive overturns the principle of traditional glue chemical adhesion. The inkjet film can be pasted repeatedly on the clean and smooth surface under the ideal environment, and does not damage the surface of attachments.

4.Low viscosity

Glue surface needs to be contacted during the pasting operation. You may not feel the glue due to low viscosity, which is liable to release film materials and beneficial to easy operation.

1.UV printing is selected and used, and exquisite images can be shown perfectly

The film coating layer makes UV ink show the best performance ability, and colorful images with rich gradation and granular sensation can be obtained.

2.Image quality can be lasted for a long time

The special PET film materials have consistent high quality, possess the outstanding properties of heat resistance, chemical resistance and wear resistance, and are more suitable for keeping images in high temperature condition because they can guarantee the clearness, fastness and non-deformation of these images.

3.Environment-friendly film materials

The film materials are produced by using regenerative PET materials, which saves material consumption and has no pollution to the environment. In addition, the void structure makes film materials light and easy to use.

4.No adhesive residue

Traditional inkjet paster is hard to realize that there is no adhesive residue, so it is required to clean the surface of attachments during peeling, which wastes time and energy and even may lead to complaints. However, Gecko Adhesive adopts physical absorption and there is no adhesive residue.

5.Easy to operation

No additional adhesive tape is needed during the pasting process. It is suitable for repeated relocation and removal. Green hands can also complete the pasting easily.

The interesting and fashionable inkjet photopaper is mainly used in various indoor scenes such as company culture boards, office clapboards, inner houses, coffee shops, bookstores, etc., and personal products such as computers, cellphones, etc.

Ordinary inkjet photopaper is still a kind of chemical adhesive by using glue, and it generally has the disadvantages of inconvenience for counterpoint due to strong viscidity, difficulty to tear down, adhesive residue remained or damage to furniture or objective surface when peeling, and containing unhealthy chemicals in the glue.

Gecko Adhesive photopaper is an innovative adhesive manner, and it uses micro-suckers to drain away the air, form the micro-vacuum and generate physical absorption, with low viscosity, easy pasting and counterpoint, removability, repeated pasting, no adhesive residue and no damage to the surface after peeling. You will have a wonderful experience.

1.It can be applied in the fields of label, inkjet photopaper, advertising inkjet, poster campaign.

2.It is recommended to be used in personal life photos, company culture photos, commercial promotion photos, etc., as well as advertising inkjet film, label film, etc.

3.It is suitable for UV printing

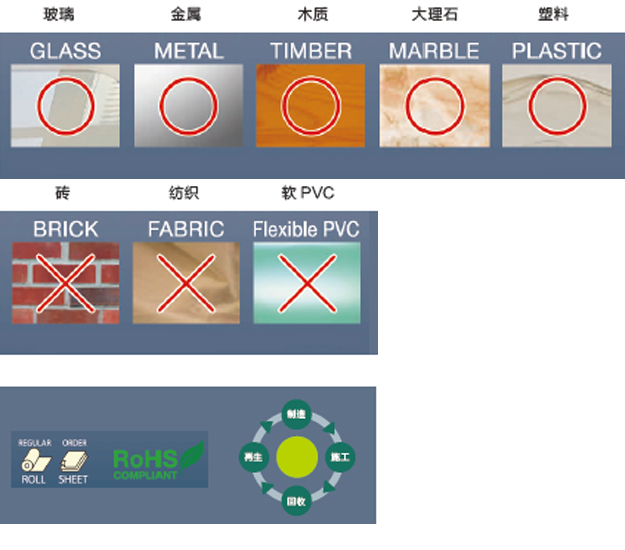

4.It is applicable to be pasted on the following materials:

1.Product appearance: roll materials

2.Product specification: roll width 1.37m * roll length 12.5/25/30/50m (The roll length can be customizable)

3.Surface materials: 280 RC Photo paper

4.Glue: 80um Gecko Adhesive, with environment-friendly water-based features and sucker physical absorption features

5.The liner: 120g release paper

6.Printing inks: UV

(*Note: Since adjustments can be made by Signscal for parameters and performance of all products according to market demand, the actual product shall prevail)